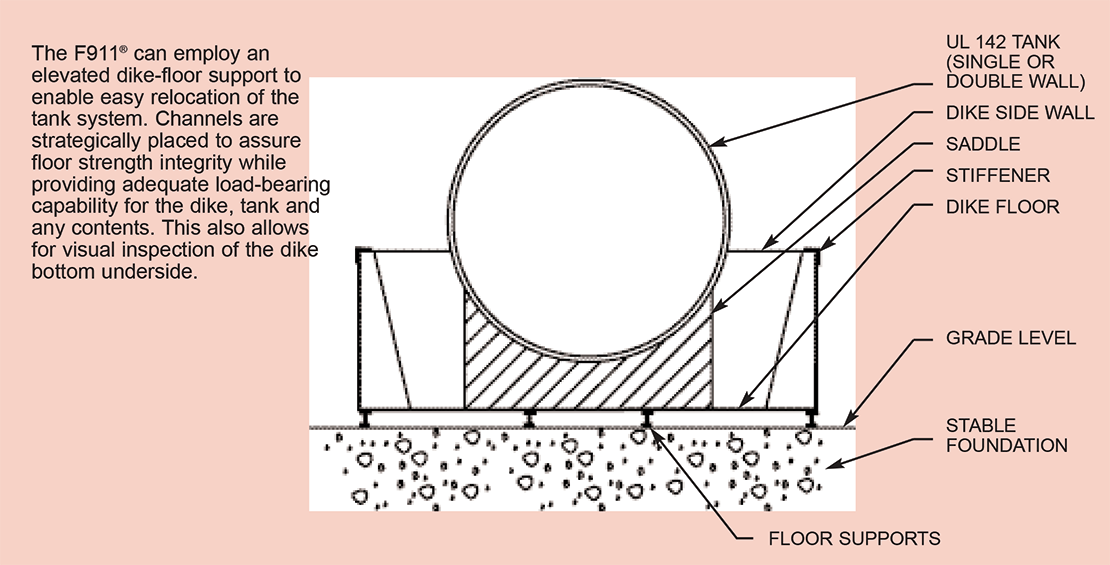

STI F911® Diked Tanks are aboveground steel storage tank systems manufactured with built-in secondary containment. The tank is supported inside an open-top dike, which has a solid steel floor and vertical steel walls. The dike allows for secondary containment, monitoring, overfill containment and recovery of product. It is easily relocated and economical to install.

Compatible with a wide range of fuels and chemicals.

STI F911® Diked Tanks Product Details

Features:

- UL 142 listed for both primary tank and secondary containment outer tank

- Diked design offers integral secondary containment to meet EPA SPCC requirements

- Built to nationally-recognized STI and UL standards

- Primary storage tank and secondary containment compatible with a wide range of fuels and chemicals

- Customized compartments can be provided for cost-effective multi-product storage

- Capacities range from 300 to 20,000 gallons

F911® Guideline Specifications:

A. General:

- Provide F911® diked aboveground storage tanks.

B. Labeling:

- Dikes shall bear the Steel Tank Institute F911® Aboveground Storage Tank identification label.

- Aboveground tanks shall bear Underwriters Laboratories UL 142 label for primary tank.

C. Product Description:

- Dikes shall be manufactured in accordance with Steel Tank Institute F911® Standard for Diked Aboveground Storage Tanks.

- Aboveground tank shall be manufactured in accordance with and listed for Underwriters Laboratories UL 142 Standard for Steel Aboveground Tanks for Flammable and Combustible Liquids.

- Tank shall be steel inner wall for primary containment.

- UL 142 listed supports shall be used for all horizontal tanks.

D. Manufacturer:

- Manufacturer shall be a licensed member company of the Steel Tank Institute and subject to Steel Tank Institute’s Quality Assurance program.

Ladders, Stairs, Platforms, Catwalks:

Internal and external ladders, stairs, platforms and catwalks are designed to comply with strict OSHA guidelines.

Tank Supports:

Greer’s tank supports are designed to keep the tank stationary and also to support and elevate the tank to minimize corrosion concerns. Our supports are available in different designs to accommodate specific installation requirements: UL saddles, skids, cradles or a variety of tank stands.

Custom Manways:

Manways provide access to the tank and include a bolted cover and gasket. A variety of designs can be ordered for your specific project.

Complete Pump Systems:

Your pump systems packages can be ordered to your specific needs. These can either be mounted on the tank, on a platform, or shipped loose for installation by others.

Fuel Guards and Spill Containments:

Our Fuel Guards are powder coated (inside and out) and are available in 5 or 7.5 gallon sizes. The tops are designed so that they may be locked. Spill containments are designed per project spec. and contains 1/2” plunger to return spilled liquids.

Alarm Gauges:

These provide detection for leak and level alarms.